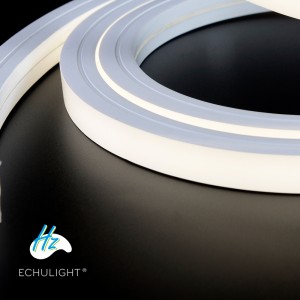

HZ-S0206

Siffofin tsari

Mahimman sigogi

| Samfura | HZ-S0206 |

|

Zazzabi / launi | 2300K |

| 2700K | |

| 3000K | |

| 4000K | |

| 6000K | |

| Daidaitaccen tsiri mai haske | 2216-240-24V-3mm |

| CRI | ?90 |

| Voltage (V) | 24 |

| Wutar lantarki (A) | 0.48 |

| Power (W/m) | 5 |

| lm/tsawon tsayi | 107 |

| 108 | |

| 113 | |

| 126 | |

| 130 | |

| Girman (mm) | 2.5×6 |

| Daidaitaccen tsayi | 5000mm |

| Naúrar Shear (mm) | 25 |

| Ƙididdigar IP | IP67 |

Hanyar waya

Sigar injina

Toshe manne

Tsarin samarwa

Sayen Kayan Kaya

1.Chip Selection: Dangane da buƙatun aikin haske, zazzabi mai launi, ma'anar ma'anar launi da sauran kaddarorin a cikin ƙirar samfur, ana siyan kwakwalwan LED masu inganci na SMD daga masu samar da abin dogaro. Waɗannan kwakwalwan kwamfuta dole ne su ɗauki tsauraran gwajin samfurin kafin siye don tabbatar da cewa kayan lantarki da na gani sun dace da ma'auni.

2.Circuit Board Procuit: Zaɓi kwamitin FPCB mai inganci mai dacewa, auna juriya na zafin jiki, aiki da sassauci, da siyan kayan aikin lantarki daban-daban da ake buƙata don samarwa a lokaci guda, kamar capacitors da resistors, duk waɗannan dole ne su cika ka'idojin inganci.

3.Auxiliary Material Procurement: Sayi kayan taimako irin su 3M m don taro taro, solder manna don waldi da manne don encapsulation da kariya, da kuma tabbatar da cewa danko, kwanciyar hankali da sauran halaye sun dace da tsarin samar da tsiri.

Tsarin Faci

1.Solder Manna Bugawa: An lulluɓe da manna mai siyar daidai akan madaidaitan ma'auni na hukumar da'ira ta FPCB. Yin amfani da ingantacciyar na'ura mai ɗorewa ta manna bugu kuma bisa ga samfurin da aka saita, kauri da sifar manna ana tabbatar da su zama iri ɗaya kuma daidai, yana shimfiɗa tushe mai kyau don facin dunƙule na gaba.

2.Ƙwaƙwalwar Ƙwaƙwalwar Ƙwaƙwalwa: Tare da taimakon injin sanyawa ta atomatik, SMD LED beads da aka saya suna da sauri da kuma daidai a haɗe zuwa pads da aka buga tare da manna mai sayarwa bisa ga tsarin zane. Na'urar hangen nesa tana kula da tsarin facinta a duk lokacin da ake aiwatarwa, kuma ana iya gyara ƴan ɓata lokaci cikin lokaci.

Duban gani

Gudanar da duba gani na hannu akan filayen LED da aka ɗora.

Sake dawo da siyarwa

1.Parameter Saitin: Bisa ga halaye na solder manna amfani da dalla-dalla na beads, a hankali daidaita sigogi na kowane zafin jiki yankin a kan reflow soldering inji, ciki har da preheating zafin jiki, dumama kudi, reflow ganiya zazzabi da sanyaya kudi. Madaidaicin saitin siga shine mabuɗin ingancin walda.

2.Welding Kisa: Sanya allon da'ira mai faci akan bel mai ɗaukar nauyi na injin sake kwarara. Yayin da allon kewayawa ke wucewa ta wurin preheating, reflow da sanyaya, bi da bi, ana dumama solder manna don narke da ƙarfafawa, sanin ingantaccen haɗin lantarki tsakanin beads da allon kewayawa. A wannan lokacin, mai aiki yana mai da hankali sosai ga yanayin aiki na kayan aiki.

Dubawa da Gyara

1. Duban gani: Gudanar da duban gani na farko na tsiri mai walda don bincika ko akwai wani nau'in siyar da kayan aiki, da bacewar soldering, ci gaba da sayar da beads, ko bead ɗin sun lalace ko sun rasa matsuguni, da kuma ko akwai wasu kurakurai ko wasu lahani a kan allon kewayawa. .

2.Power-on Gwajin: Haɗa tsiri zuwa madaidaicin wutar lantarki na 24V, lura da yanayin haske na beads, duba ko hasken ya kasance iri ɗaya, ko akwai hasken stroboscopic kuma ko yanayin zafin launi yana da al'ada. Alama samfuran da suka lalace kuma shirya ƙwararrun ma'aikatan kulawa don gyara su.

Neon Extrusion

1.Materials Mixing da Processing: Ƙara ƙwaƙƙwaran albarkatun silicone da ƙari irin su vulcanizing jamiái zuwa mahaɗin a cikin wani ƙayyadadden rabo da motsawa kuma juya har sai daɗaɗɗen silicone ya zama cikakke. Don wasu buƙatu na musamman na tube masu haske, yana iya zama dole don ƙara masterbatch launi da sauran kayan don daidaita launi.

2.FPCB Sarrafa Kwamitin Gudanarwa:Kwamitin sassauƙa na FPCB tare da shigar da beads na LED da kuma kammala sayar da sake kwarara yana ƙarƙashin maganin girgiza tsufa don gwada kwanciyar hankali da amincinsa. Bayan girgizar tsufa, ana sanya dukkan allo mai sassauƙa na FPCB akan benci na aiki wanda aka lulluɓe shi da fata mai tsattsauran ra'ayi don rabuwar hukumar kuma an raba shi zuwa filaye masu sassauƙa na FPC guda ɗaya. Kuma ana gwada hasken kowane bead na LED, kuma an naɗe waɗanda suka cancanta.

3.Extrusion: Raba zuga da uniform m silicone kamar yadda ake bukata, sa'an nan aika da FPC m tsiri a cikin extruder sanye take da extrusion mutu, da kuma aika raba m silicone. A lokaci guda, kunna tanda da kuma extruder kuma fara extrusion da baking curing. A lokacin aikin extrusion, narkakken silicone na filastik yana motsawa gaba a ƙarƙashin jujjuyawar dunƙule kuma ya wuce ta cikin mutuwar extruder. Screw da mutu na extruder suna matsa lamba akan narke don fitar da shi a cikin hannun riga ko harsashi na ratsin haske na Neon daidai da siffar da girman mutu kuma ku nannade allon FPC a ciki.

Sanyaya da Siffatawa

1.Cikin sanyaya: Fitar hasken Neon da aka fitar nan da nan ya shiga cikin na'urar sanyaya, kamar tankin ruwa mai sanyaya ko na'urar sanyaya iska, ta yadda silicone ɗin ya yi sauri ya kwantar da ƙarfi tare da kiyaye siffar da girma a lokacin extrusion.

2. Siffata:Wutar hasken Neon bayan sanyaya yana da ƙayyadaddun tauri da kwanciyar hankali kuma ana iya sarrafa shi kuma a bi da shi daga baya.

Gudanarwa na gaba

1.Yanke da Gyara: Yanke da datsa tsiri mai haske na Neon da aka fitar bisa ga tsawon da ake buƙata. Yawancin lokaci, za a yi amfani da kayan yankan kayan aiki ko kayan aikin yanke don yanke igiyar haske a cikin daidaitattun tsayi.

2.Bincike da Gwaji: Yi duban bayyanar, gwajin wutar lantarki, da dai sauransu a kan raƙuman haske na neon tare da shigar da beads masu haske don bincika ko yanayin fitarwar haske, daidaiton launi, aikin lantarki, da dai sauransu na ƙullun haske sun cika buƙatun kuma cire samfurori marasa lahani.

Taruwa da Marufi

1.Assembly na Na'urorin haɗi: Manna 3M m a kan gwajin cancantar tsiri don sauƙaƙe shigarwa na gaba. Don tarkace mai hana ruwa, za a yi ƙarin maganin rufewa, kuma za a ƙara riguna masu hana ruwa, gaskets na roba da sauran abubuwan da aka gyara.

2.Marufi da Ware Housing: Wind da kunshin tube a cikin tsari bisa ga daidaitaccen tsayin daka, kamar 5000mm a kowace na'ura, saka fim ɗin filastik da marufi, haɗa alamar samfurin, yana nuna ƙayyadaddun bayanai, samfurin, kwanan watan samarwa da sauran bayanai, sannan motsawa. su zuwa sito domin ajiya, jiran kaya.

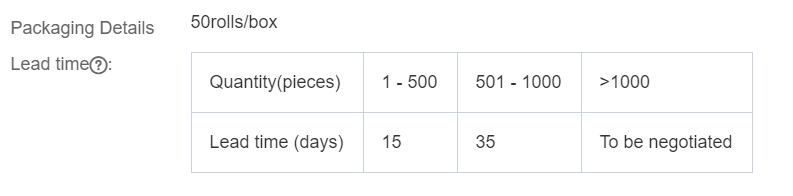

Marufi & bayarwa

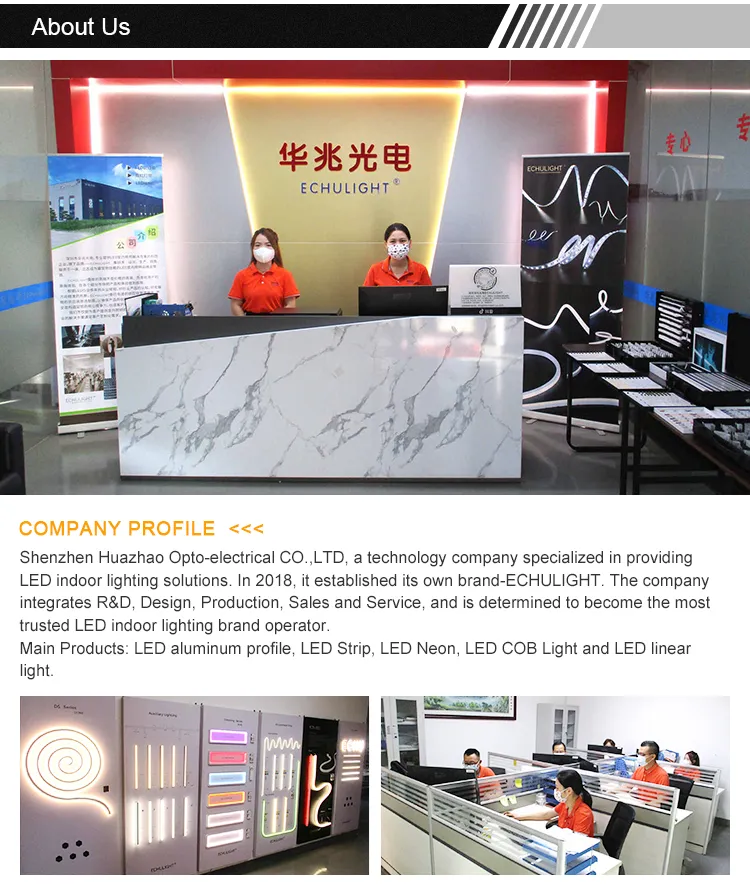

Game da Mu

Masana'antar mu

Amfaninmu

Takaddun shaida

Shipping & Biya

FAQ

Masu alaƙaKAYANA

-

Waya

-

Imel

-

Sama